A brand-new series of locks created especially for modern needs. An electronic circuit board inside the motorized lock includes all anti-robbery, anti-theft, valuables transport control features

HAL 600

HAL 600 series Digital Lock

Compact and highly flexible with multi-user opening, record of events, serial controlled emergency opening, control of five motorized locks and identification with electronic Secur Key (Dallas reader/writer), this lock is the ideal system for managing the opening all safes.

Either the digital keypad or the electronic Secur Key (Dallas reader/writer) can be used for the various functions, it being possible to mix means of identification.

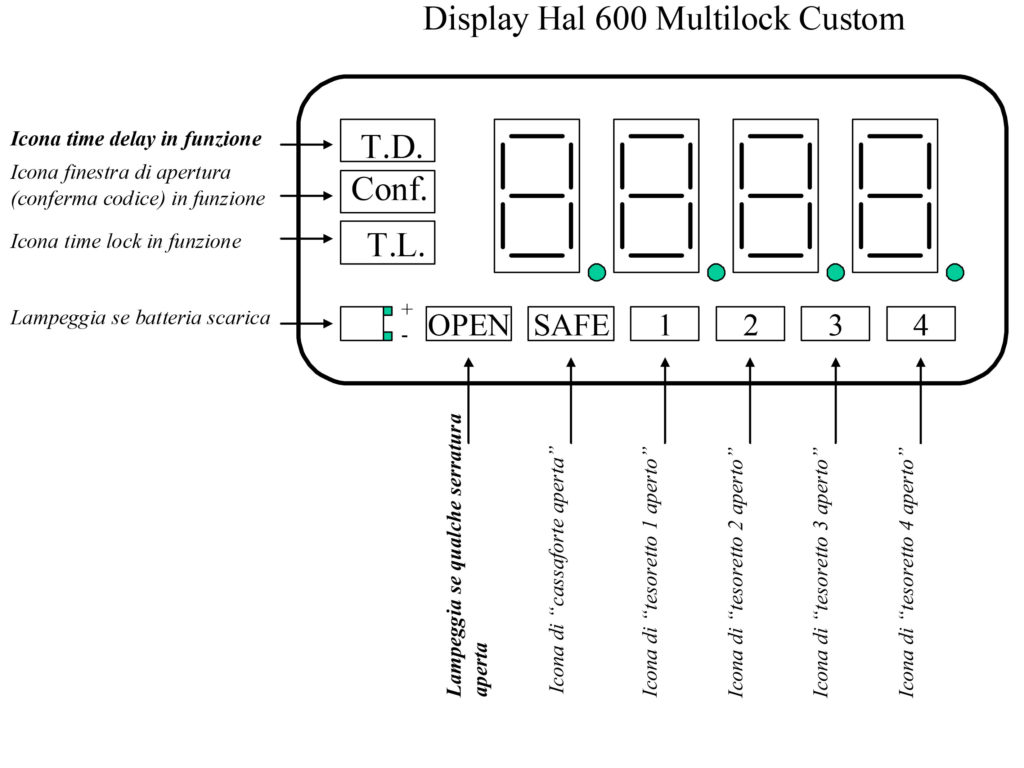

Icons on a new, specially designed display signal status of lock and all functions.

The lock comprises:

1 Control console complete with keypad, liquid crystal display, sensor for electronic Secur Key and touch sensor (optional)

Up to 5 motorized locks with expanded self-driven, self-blocking bolt complete with electronic circuit board and emergency opening.

Up to 10 locks with graphic display

DESCRIPTION

1° The lock bolt should be motorized

This gives a series of advantages such as:

- The lock can be mounted in strategic points which are invisible from the outside, as opposed to manual locks with a knob which can easily be seen. The knob is indispensable to push home the lock bolts.

- A motorized lock bolt allows both remote controlled and above all automatic locking. It is not possible to forget to lock, as can be done with a manual lock with knob.

- A motorized lock bolt makes locking more flexible if it is used for timed opening of the safe, as it automatically re-closes after a timed opening in such a way that opening is always timed (impossible with a manual type which if left open, either purposely or forgotten will cancel the timing of subsequent openings). This is further aggravated when the Time Lock function is used.

- Motorization becomes indispensable when a number of locks are involved. For example, if two electro-magnetic locks are mounted on an ATM, it is essential to open them quickly and at the same time since the electro-magnetic lock stays active only for a few seconds. It is easy to imagine the difficulties if a number of people with different codes are involved and the lock is timed. With a motorized lock this problem clearly does not exist and it becomes truly multi-user.

2° The electronic functions

The electronic functions should be complete, programmable and flexible.

- Delayed opening, window for opening are now standard

- Automatic time lock is indispensable

- Multicodes -Master, Manager and User are now standard

- Joint opening, with a number of codes, is now normal

- Electronic anti-tampering is also standard

Special functions make the difference, such as:

- Option to cancel timing at certain times

- Option to cancel timing with electronic key which leaves a trace in memory of events

- Assignment of various functions to Master, Manager and User codes

- Opening or consent to open “mixing” the options – codes or electronic key.

- Option for cascade connection of a number of locks to make all locks electronic

- Time allowance – option of non-delayed opening for a short time (very useful on ATMs for example).

- Automatic time lock (very useful on ATMs situated outside the branch to ensure cash just loaded cannot be removed under coercion. In this event time delay is of no value, on the contrary it creates problems for reloading).

- Automatic closure on programmed and standard public holidays

- Automatic change to daylight saving time

- Real time calendar

- Memorization of events for each lock

- Serial port for programming, programming control, reading and printing events.

- Remote alarm

- Silent alarm

- Bolt open/closed sensor

- Local and remote locking

- Controlled electronic emergency opening – In the event of damage to the main circuit board ensures safe can be opened with all criteria for maximum security (not with a simple combination of mechanical means) and not broken open.

- Special software for management of valuables transport.

LEM makes the mechanical parts, the electronics and the software for the locks.

FEATURES

The features of this lock are highly flexible and advanced – they are not described in detail here as they are determined by common agreement with the customer.

Controls the codes with means and functions specified by the customer.

It has all features for remote control

It has all features for secure control by valuables transporters.

Can be installed on all safes, particularly where bolts have to be drawn to close – see Cen III ATM.

MAIN TECHNICAL CHARACTERISTICS

- 1 x 8 or 9 number Master code for programming

- 3 x 8 or 9 number Manager codes

- 10 user/multi-user codes

- Lock opening with code and electronic key (Dallas reader/writer)

- Time delay 1 -99 minutes

- Opening window 1 – 99 minutes

- Time allowance to open without time delay after closing

- Time lock

- Daily programmed time locks – up to four periods

- Cancel time delays up to two a day

- Programmed automatic closure for public holidays

- 4 automatic closures to be activate at will on an annual basis

- Clock/calendar with automatic adjustment for daylight saving time

- Cyclic memorization last 1,000 events

- Electronic anti-tampering

- Remote anti-coercion alarm with additional relay board

- Programming functions and parameters through serial line with safety code (RS232-RS485 )

- Emergency opening with double cryptographic key.

- Remote reading of lock status – open/closed, blocked, in alarm etc

- Lock/Unlock open with serial line

- Lock/Unlock open with dedicated optoisolated port

- Option to annul time delay with electronic SecurKey or remote

- Buzzer for keypad feedback or error alert

- “Combination expired” signal programmable months of validity

- Battery low alert

- Bolt open sensor

- Option to interlock opening

- Software for PC

- Separate circuit board for emergency opening (ask LEM for details)

- Board for emergency opening

- Opening control with “Dynamic†codes

- Presetting and software for centralization – remote controls, remote signals with TCP/IP network board.

ADDITIONAL FEATURES

- Extraordinary opening with codes and dedicated electronic keys and memorization of event (code or code plus key)

OPENING MANAGEMENT OPTIONS AVAILABLE ON REQUEST

- Management of electronic keys by programming the number of openings allowed for each key.

- Key enabled to open one or more locks

- Memorization of opening on electronic key

- Opening with dynamic code (ask LEM for specific information)

- Opening with fingerprint

- Managing software for the above functions

As LEM manufactures both the locks and the software, it is able to modify the functions for other types of opening management.

THE LOCK IS CERTIFIED TO EU STANDARD EN1300, WITH CLASS “B” CUSTOM DIPLAY, CLASS “C” 16 X 2 GRAPHIC DISPLAY “C”

A new console with graphic display has been designed for control of a number of locks or for use of fingerprints. For improved lock management this display can provide multiple information simultaneously compared with custom or 16×2 displays.

The touch sensor is latest generation with micro pressure sensors.

QThis new technology is more reliable than previous biometric sensors based on optic technology and has the advantage of being easier to use since it provides a perfect reading of the fingerprint even in the presence of dirt on the sensor, or sweaty, wet or not perfectly clean hands.

NEW HAL600 console

A new console with graphic display has been designed for control of a number of locks or for use of fingerprints. For improved lock management this display can provide multiple information simultaneously compared with custom or 16×2 displays.

The touch sensor is latest generation with micro pressure sensors.

QThis new technology is more reliable than previous biometric sensors based on optic technology and has the advantage of being easier to use since it provides a perfect reading of the fingerprint even in the presence of dirt on the sensor, or sweaty, wet or not perfectly clean hands.